MH502 – Setting Up the Material Handling AX (MHAX) Module in Dynamics 365 Finance and Operations

Integrating the Material Handling AX (MHAX) module in Dynamics 365 Finance and Operations (D365FO) can significantly streamline and enhance your warehouse and distribution operations. Here, we will walk through the basic setup, key configurations, and settings necessary to get the MHAX module up and running effectively.

Table of Contents

Toggle1. Turn on the MHAX Feature

- Go to System administration > Workspaces > Feature management.

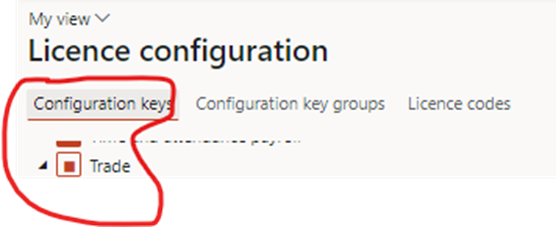

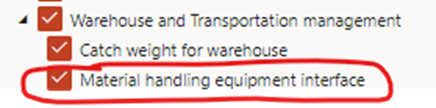

- Turn on the feature named Material handling equipment interface.

- If you’re using Supply Chain Management version 10.0.28 or earlier, put your system into maintenance mode, go to System administration > Setup > License configuration, expand Trade > Warehouse and Transportation management, and select the Material handling equipment interface checkbox. Then, turn off maintenance mode,

- If you’re using Supply Chain Management version 10.0.29 or later, In the Feature management workspace, locate the feature named Material handling equipment interface. Since version 10.0.29, this feature is enabled by default and cannot be disabled.

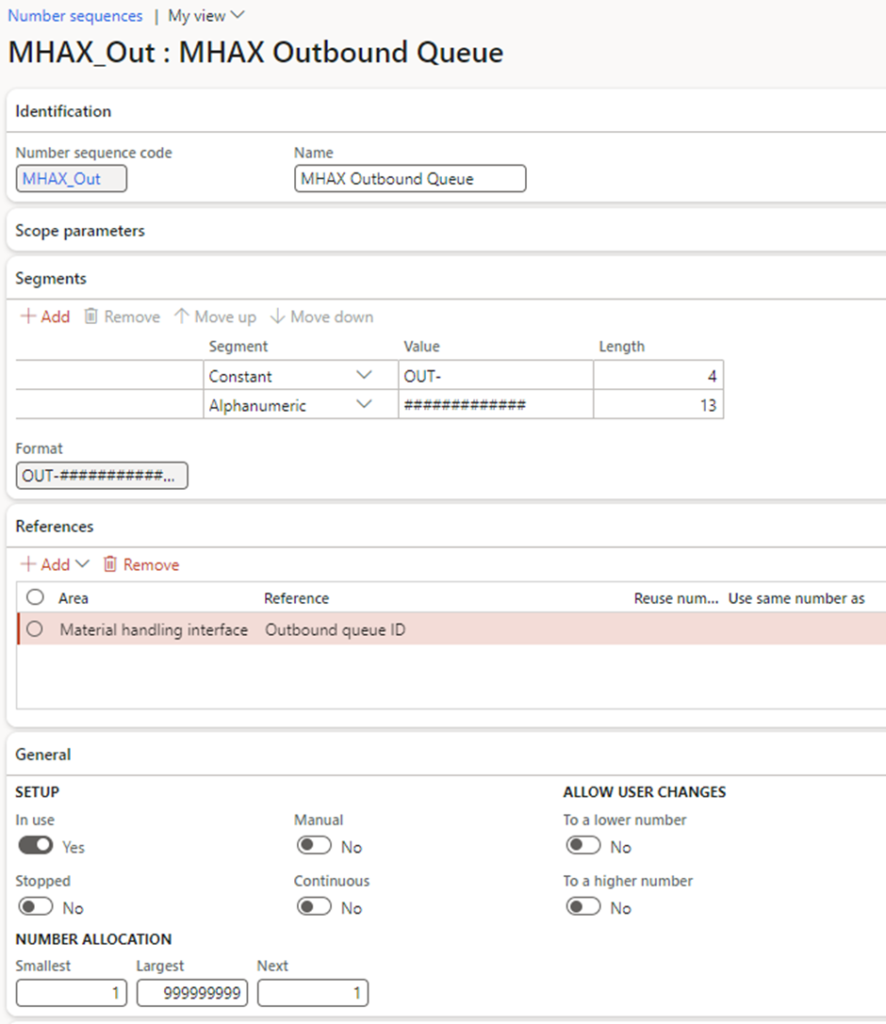

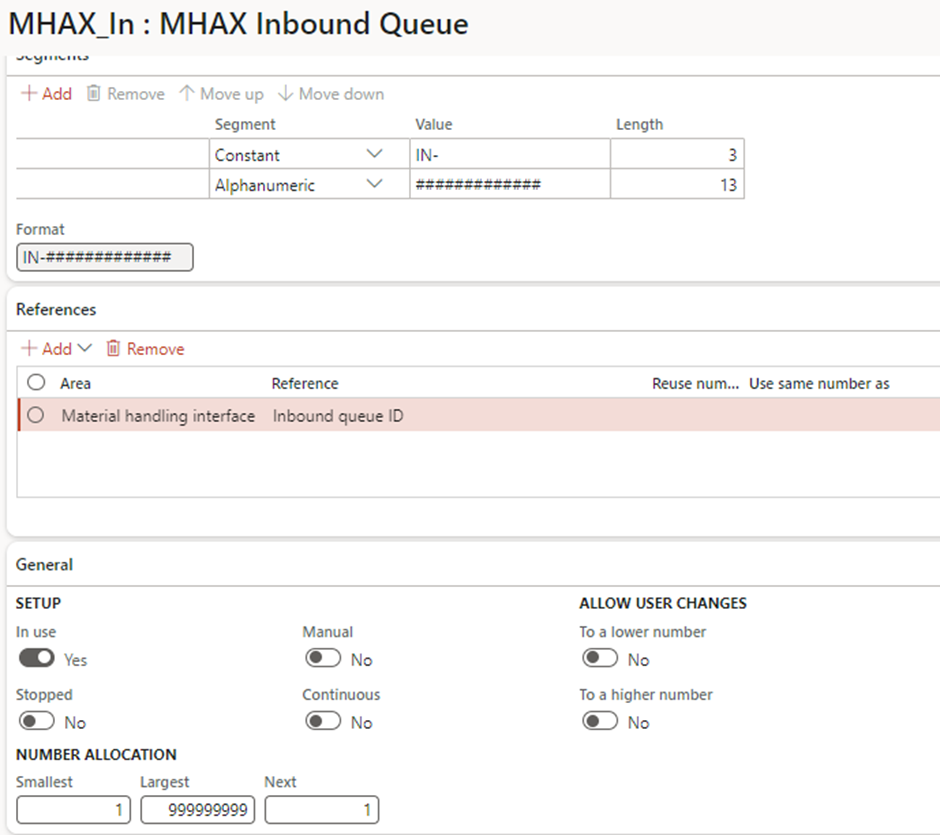

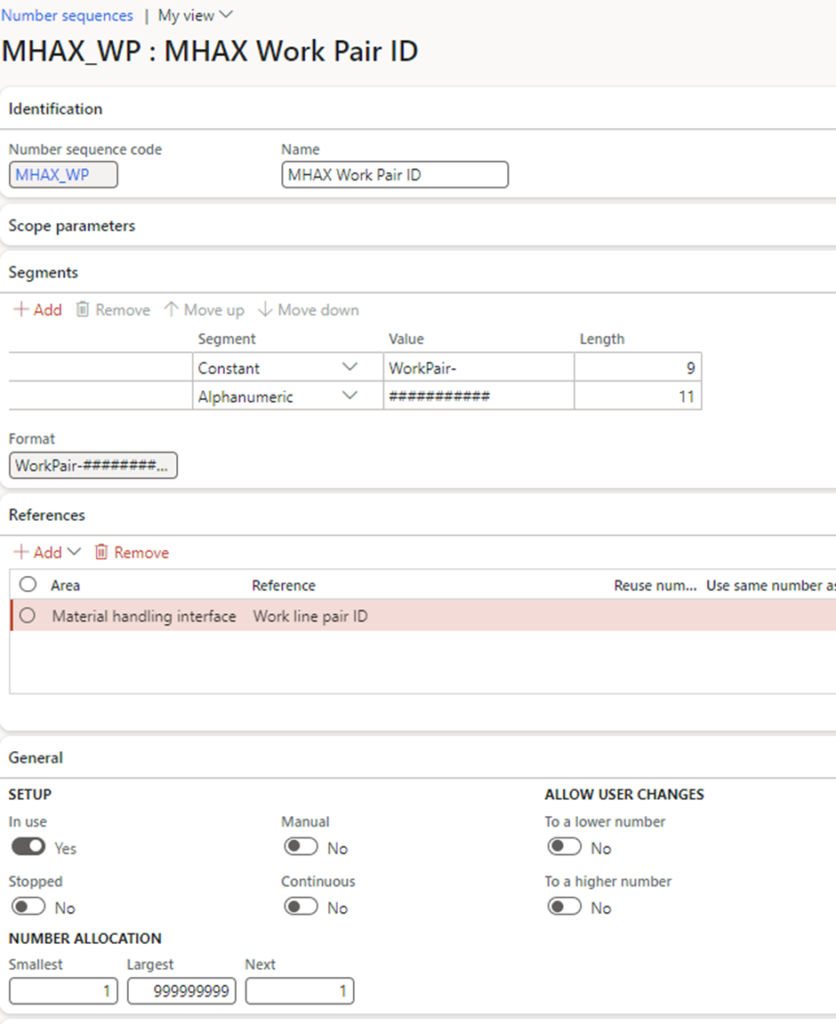

2. Number Sequences

- Outbound Queue ID: Dynamics WMS generates outbound events based on work lines created during various work creation and execution processes. The MHAX system polls the WMS for new events and processes them.

- Setup Non continuous number sequence and Give Number sequence a meaningful name i.e. Out-xxxxxxx

- Inbound Queue ID: After handling the events, the MHAX system sends inbound events back to the WMS, which processes them immediately.

- Setup Non continuous number sequence and Give sequence a meaningful name i.e. In-xxxxxxx

- Work Line Pair ID: A unique identifier that groups together pick and put lines for individual warehouse work. Setup Non continuous number sequence and Give sequence a meaningful name i.e. WorkPair-xxxxxxx

In contrast to the Work Line Pair ID, the RecID is unique for each work line transaction.

Both the Work Line Pair ID and RecID are essential for closing warehouse work transactions based on inbound response receipts from the external MHAX system. We will explore this further in upcoming articles during scenario testing.

3. Setup

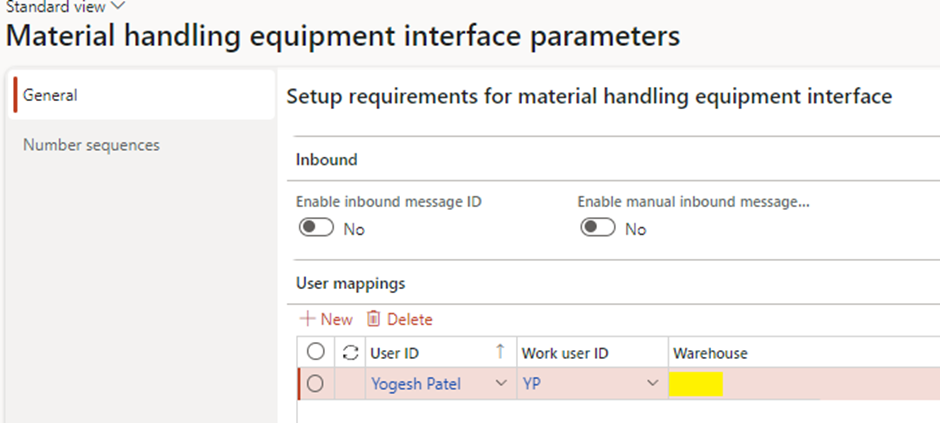

1. MHAX Parameters

- Navigate to Material handling equipment interface > Setup > Material handling equipment interface parameters.

- On the General tab, set the following fields:

- Enable Inbound message ID: This button ensures that each incoming message from the external MHAX system to Dynamics has a unique identifier. Think of it like giving each incoming package a unique tracking number so you can easily identify and manage it.

- Keep it turned-off. This will help during message retries as a part of error handling. Don’t worry as Dynamics will throw an error if you try to pass message for closed transaction.

- Enable manual message ID: This button allows you to manually create and assign IDs to incoming messages. It’s like being able to create your own tracking numbers for packages that you receive, which can be useful if you need to simulate or test the system.

- User mappings: Map system users to their related warehouse workers Warehouse management > Setup > Worker

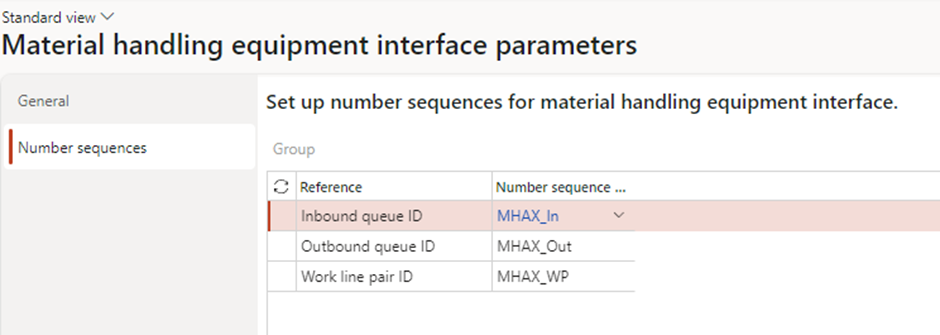

- On the Number Sequence tab, set number sequence created above in the following fields:

- Inbound Queue ID

- Outbound Queue ID

- Work Line Pair ID

2. Subscriptions Overview

Subscriptions play a crucial role in ensuring that different parts of the system stay updated and in sync. Let’s break down what subscriptions are and how they work.

What is a Subscription?

A subscription in the MHAX module is like a notification system. Imagine it as signing up for alerts or updates about specific activities or changes that happen within the warehouse management system. When certain events occur, the system automatically notifies the relevant equipment or processes that are subscribed to these events.

How Do Subscriptions Work?

- Event Creation: When something happens in the warehouse, like a new order arriving or a task being completed, an event is created in the system.

- Notification Sending: The system checks to see which equipment or processes are subscribed to this type of event.

- Action Triggered: The subscribed equipment or process receives the notification and takes the appropriate action. For example, if a MHAX system is subscribed to “Sales order released to the warehouse” events, it might start reserving stock in External WMS and get robots ready to pick items.

Setting Up Subscriptions in MHAX

- Identify Key Events: Determine which events in your warehouse operations need to trigger actions. Common events might include receiving shipments, completing picking tasks, or moving items.

- Configure Subscriptions: Material Handling equipment Interface > Setup > Subscriptions and configure the subscriptions for your equipment. This involves specifying which events each piece of equipment should be notified about.

- Test the System: Once subscriptions are set up, test the system to make sure events are being recorded correctly in Outbound and Inbound message queue in Dynamics.

- Monitor and Adjust: Continuously monitor the performance of your subscriptions. Don’t worry as Subscriptions setup is flexible and can be changed anytime you want.

Key Components

- Subscription ID: A unique identifier for each subscription event. This ID is mandatory for outbound events consumption.

- Description: A comprehensive description of the subscription event.

- Warehouse: The designated warehouse for the subscription event.

- Outbound Transaction Type: The type of event for outbound transactions.

- Run Query: Enables the editing of queries for advanced filtering of each event type.

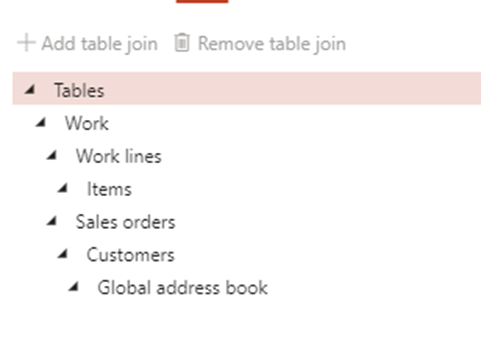

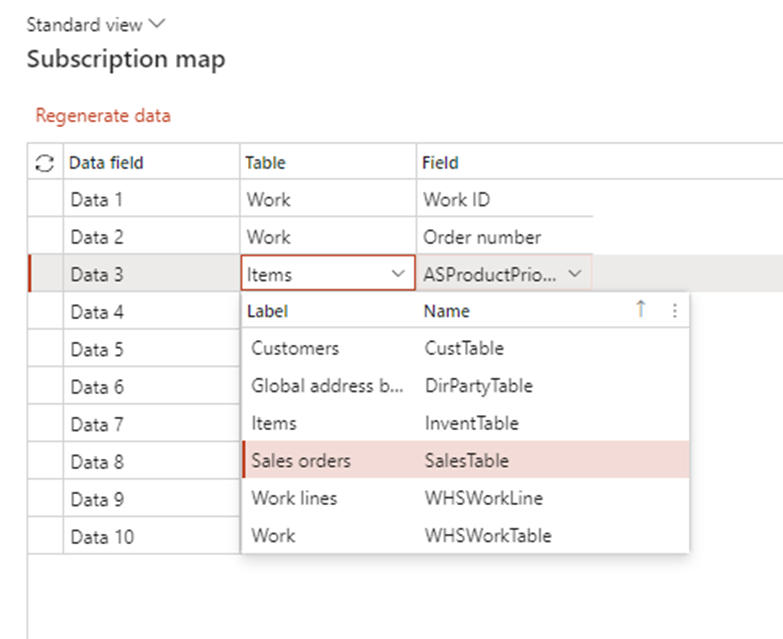

Tips: Edit queries allow joins for other table i.e. Item, Customers, Sales orders etc.

- Subscription Map: Specifies the fields to be included in the outbound message, limited to 10 fields. Default tables are Work and Worklines for fields selection.

Tips: You can join table under edit query and tables will be available under subscription map

- Payload Generator: Additional data fields that needs to be sent to external MHAX along with subscription Map field. The content of these fields is generated by X++ code.

Later part of this series, we will configure key subscriptions.

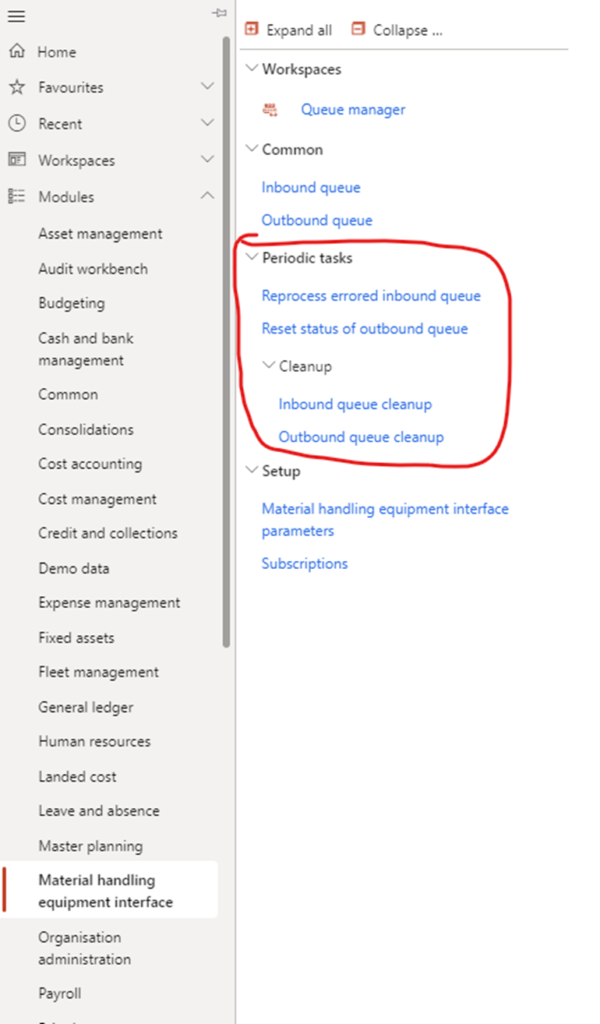

4. Periodic Tasks

1. Reprocess Errored Inbound Queue (Optional)

- This task automatically attempts to fix and reprocess any errors that occurred when data or instructions were coming into the system (inbound). For example, inbound message failed due to standard configuration in D365. Post fixing configuration, failed messages can be resent without resending from external MHAX

2. Reset Status of Outbound Queue

- This task resets the status of messages or instructions that have been sent out of the system (outbound) but haven’t been processed correctly by the external MHAX. Resetting the status allows the system to attempt sending or processing the message again.

3. Inbound Queue Cleanup

- This task clears out old or unnecessary records from the inbound queue—these are the logs and data from previous inbound transactions that have already been processed and are no longer needed.

- Regular cleanup prevents the system from becoming cluttered with old data, which could slow down processing and reduce efficiency.

4. Outbound Queue Cleanup

- Similar to the inbound queue cleanup, this task removes old or unneeded records from the outbound queue—these are records of tasks or messages that have been successfully sent out and processed.

- Keeping the outbound queue clean ensures that the system remains fast and efficient, without getting bogged down by unnecessary data.

5. Common

1. Inbound Queue

The Inbound Queue menu is used to manage and monitor messages or data that are received from external material handling equipment. The information typically involves updates from automated systems regarding the status of inventory, movements, and other warehouse operations.

- Purpose: To track and process incoming messages from external material handling equipment.

- Content: The queue contains records of messages received from external systems, such as confirmations of completed tasks (e.g., Picklist, goods received, items moved).

- Process: These messages are processed by the system to update the corresponding warehouse management records within D365FO.

- Management: Users can review, process, or reprocess these inbound messages if there are errors or issues that need correction.

2. Outbound Queue

The Outbound Queue menu handles messages or data that are sent out from D365FO to external material handling equipment. This typically involves instructions or commands for automated systems to execute warehouse operations, like picking, moving, or storing goods.

- Purpose: To manage the dispatching of instructions or data to external material handling systems.

- Content: The queue contains records of messages or commands that are sent from D365FO to the external systems. These might include instructions for order picking, inventory movements, or storage assignments.

- Process: Once messages are sent to the external equipment, they are tracked in this queue until confirmation of completion, or an error is received.

- Management: Users can monitor the status of these outbound messages, re-send failed messages, and ensure that warehouse operations are synchronized with the material handling equipment.

6. Queue Manager Workspace

Overview of the Queue Manager Workspace

1. Purpose:

- The Queue Manager workspace is designed to provide a comprehensive view and control over both inbound and outbound communication queues. It enables warehouse managers and IT administrators to monitor, manage, and troubleshoot the flow of data between D365FO and external systems.

2. Key Features:

- Real-Time Monitoring: Displays real-time data on the status of inbound and outbound messages, including successful transactions and errors.

- Error Handling: Allows users to identify and correct errors in the communication process, such as failed messages or unprocessed transactions.

- Reprocessing Capabilities: Provides tools to reprocess failed messages or resend instructions to external equipment, ensuring that all tasks are eventually completed.

- Detailed Views: Users can drill down into specific queues to view details about individual messages, their content, and processing status.

- Custom Filters and Sorting: Offers filtering and sorting options to focus on specific types of messages or priority issues.

3. Sections of the Workspace:

- Inbound Queue Overview: Displays a summary of messages received from external systems, including their status (e.g., pending, processed, error).

- Outbound Queue Overview: Summarizes messages sent to external systems, tracking their status and any issues encountered.

- Error Logs: A dedicated section to view and manage error messages, with tools for troubleshooting and resolution.

- Performance Metrics: May include key performance indicators (KPIs) for monitoring the efficiency of the integration, such as the number of processed messages per hour, average processing time, etc.

Best Practices for Utilizing the Queue Manager Workspace

- Regular Monitoring:

- Routine Checks: Regularly monitor the Queue Manager workspace to ensure that all queues are functioning smoothly. Look for any backlogs or errors that might indicate issues with the integration.

- Set Alerts: Configure alerts for critical errors or issues, so you can respond quickly to any disruptions in the communication process.

- Efficient Error Handling:

- Immediate Attention to Errors: Address errors as soon as they appear in the workspace. Investigate the root cause of the problem, whether it’s a configuration issue, a network problem, or an error in the external system.

- Use Reprocessing Tools: Utilize the reprocessing tools available in the workspace to quickly resend or reprocess failed messages, minimizing disruption to warehouse operations.

- Optimize Queue Performance:

- Review Performance Metrics: Regularly review the performance metrics provided in the workspace to identify any bottlenecks or inefficiencies in the message processing.

- Adjust Queues as Needed: Based on the performance data, you may need to adjust the settings or prioritization of certain queues to optimize the overall flow of data.

- Proactive Maintenance:

- Regular Updates: Keep the D365FO system and the MHAX module updated with the latest patches and updates to ensure compatibility with external systems and to benefit from performance improvements.

- Documentation: Maintain proper documentation of all customizations and configurations related to the Queue Manager, so that troubleshooting can be done efficiently.

- Training and Access Control:

- Train Key Users: Ensure that all relevant personnel are properly trained to use the Queue Manager workspace, including understanding how to interpret the data and handle errors.

- Controlled Access: Limit access to the Queue Manager workspace to trained personnel only, to avoid accidental changes or mismanagement of the queues.

Expand Your Knowledge: See More Material Handling Blogs

I am Yogeshkumar Patel, a Microsoft Certified Solution Architect and Enterprise Systems Manager with deep expertise across Dynamics 365 Finance & Supply Chain, Power Platform, Azure, and AI engineering. With over six years of experience, I have led enterprise-scale ERP implementations, AI-driven and agent-enabled automation initiatives, and secure cloud transformations that optimise business operations and decision-making. Holding a Master’s degree from the University of Bedfordshire, I specialise in integrating AI and agentic systems into core business processes streamlining supply chains, automating complex workflows, and enhancing insight-driven decisions through Power BI, orchestration frameworks, and governed AI architectures. Passionate about practical innovation and knowledge sharing, I created AIpowered365 to help businesses and professionals move beyond experimentation and adopt real-world, enterprise-ready AI and agent-driven solutions as part of their digital transformation journey. 📩 Let’s Connect: LinkedIn | Email 🚀

Post Comment